Two Navy F/A-18 Super Hornets launch from the USS Theodore Roosevelt in the Pacific Ocean, April 29, 2021.

Providing up-to-date information, news and original content on American Military issues.

Two Navy F/A-18 Super Hornets launch from the USS Theodore Roosevelt in the Pacific Ocean, April 29, 2021.

Marine Corps Maj. Sarah Culbertson browses for books for her children, Kyle and Rachel, before beginning her work day in Carlsbad, Calif., May 3, 2021. In addition to being a mother of two, Culbertson is a military spouse and active-duty officer.

Marines and soldiers load an M983A4 light equipment transporter and an M903 launcher trailer onto the USNS Guam during a joint mobility exercise at Naha Military Port in Okinawa, Japan, April 21, 2021. The exercise tested the capability of lift support to units and gear that are uncommon to traditional Marine Corps conveyance planning.

The Thunderbirds, the Air Force’s flight demonstration team, perform at the Sound of Speed Air Show in St. Joseph, Mo., May 2, 2021.

Arizona Army National Guard Cpl. Lehy Martinez holds his 4-year-old son while family members take photos during a send-off ceremony at Papago Park Military Reservation in Phoenix, May 2, 2021. Martinez and more 80 than other Arizona Guard soldiers were preparing to head to the Middle East for nine months to support operations Inherit Resolve and Spartan Shield.

May 4, 2021 | BY Dave Vergun , DOD News

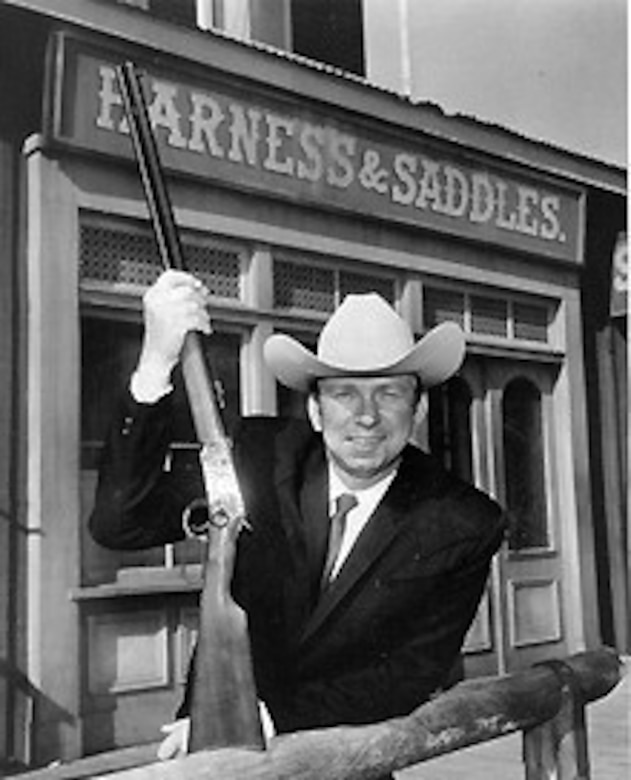

Louis Burton Lindley Jr., born June 29, 1919, in Kingsburg, California, is better known by his stage name Slim Pickens.

He grew up on a dairy farm where there were a lot of daily chores. Pickens grew restless with farm life, and as a teenager, he enjoyed going to the rodeo to ride broncos and rope steers.

His father didn't approve of his rodeo gig and wanted him to concentrate on farming instead.

As a result, Pickens sneaked off to the rodeo, going by the nickname Slim Pickens, to ensure his father wouldn't be able to track his whereabouts.

After high school, Pickens continued in the rodeo as a clown, a bullfighter and as a member of the Cowboy's Turtle Association, the forerunner of the Rodeo Cowboys Association and today's Professional Rodeo Cowboys Association. According to the ProRodeo Hall of Fame, the organization was named the Cowboys Turtle Association because they were slow to organize, but eventually "stuck their neck out." The organization wanted to ensure fair prize money, equality in judging and honest advertising of the sport.

As a rodeo clown and bullfighter, he appeared in top venues like The Cow Palace, The Calgary Stampede, Cheyenne Frontier Days and the Pendleton Round-up.

During World War II, he enlisted in the Army. When the recruiter asked him his profession, he told him "rodeo." The recruiter, being hard of hearing, thought he said "radio," and assigned him to an Army radio station in the Midwest, where he remained for the duration of the war.

The 1950s and 1960s were the heyday of cowboy and western films and TV series. Nearly all the actors who played these parts had never been cowboys or even knew how to ride horses, and stuntmen usually doubled for them in difficult riding scenes. But Pickens was different.

Pickens got noticed in Hollywood for his rodeo skills, riding ability, rugged looks and natural cowboy way of speaking and soon got parts in films such as the "Western Rocky Mountain" (1950) starring Errol Flynn; "Old Oklahoma Plains" (1952); "Down Laredo Way" (1953); "Tonka" (1959); "One-Eyed Jacks" (1961) with Marlon Brando; "Major Dundee" (1965) with Charlton Heston; "Stagecoach" (1966); "An Eye for an Eye" (1966); "Never a Dull Moment" (1968); "The Cowboys" (1972) with John Wayne; "The Getaway" (1972) with Steve McQueen; "Pat Garrett and Billy the Kid" (1973); "Ginger in the Morning" (1974); "Blazing Saddles" (1974); "Rancho Deluxe" (1975); "Beyond the Poseidon Adventure" (1979); and "Tom Horn" (1980).

The most memorable role for Pickens was in the 1964 dark comedy, "Dr. Strangelove," in which he played a B-52 bomber pilot who rides rodeo-style astride a hydrogen bomb, that is dropped on a Soviet city, starting World War III.

Pickens also appeared in many TV series, including: "The Man From U.N.C.L.E.," "The Wide Country," "Gunsmoke," "Bonanza," "Hee Haw," "The Virginian," "Route 66," "The Lone Ranger," "Maverick," "The Love Boat" and "Kung Fu."

Pickens lived with his wife in Columbia, California, not more than 150 miles from where he was born. He died on Dec. 8, 1983, after surgery for a brain tumor. He was 64.

Pickens' universal appeal and enduring renown in a uniquely American profession — the American cowboy — manifests in the accolades he has received from the many institutions that pay tribute to that heritage.

In 1982, Pickens was inducted into the Western Performers Hall of Fame at the National Cowboy & Western Heritage Museum in Oklahoma City, and in 1986, Pickens was further honored by posthumous induction into the Rodeo Historical Society's Rodeo Hall of Fame at the NC&WHM.

In 2005, Pickens was posthumously inducted into the ProRodeo Hall of Fame in Colorado Springs, Colorado, for his work as a rodeo clown, and in 2006, Pickens was inducted into the Pendleton Round-Up and Happy Canyon Hall of Fame in Pendleton, Oregon.

In 2020, Pickens was posthumously inducted into the Ellensburg Rodeo Hall of Fame in Ellensburg, Washington.

Perhaps one of the greatest tributes of all is the lifelong honor that only a younger brother can provide an older sibling: Samuel, Pickens' younger brother, was also an actor and went by the stage name Easy Pickens.

The Coast Guard cutter Hamilton arrives in Batumi, Georgia, May 4, 2021, for engagements with Georgian coast guard leaders and other Georgian representatives.

The Blue Angels, the Navy’s flight demonstration squadron, perform during an air show over Corpus Christi, Texas, May 2, 2021.

Army Sgts. Lacey Semansky and Caitlin Brody and Sgt. 1st Class Heather Harmon, members of the U.S. Army Japan Band’s Fuji Winds woodwind quintet, perform at Camp Zama, Japan, May 3, 2021.

Soldiers assigned to the Arizona Army National Guard distribute food and supplies at a drive-thru food bank on the Navajo Nation in Fort Defiance, Ariz., April 30, 2021. More than 900 of Arizona’s National Guardsmen continue to assist communities at vaccination sites and food banks across the state.

An 82nd Airborne Division paratrooper gets tested for COVID-19 at Fort Bragg, N.C., May 3, 2021. The testing is in preparation for participation in Swift Response 21 -- a joint, multinational airborne exercise involving more than 7,000 paratroopers from 10 NATO nations.

May 4, 2021

When the COVID-19 pandemic struck the U.S. in early 2020 and overwhelmed the supply of personal protective equipment, the Defense Department's Manufacturing Innovation Institutes leveraged its public-private partnerships to enable manufacturers to quickly pivot and ramp up production to respond to frontline health care workers' PPE needs and protect Americans against COVID-19 exposure.

The institutes within the MII receive funding and guidance from the DOD's Office of the Undersecretary of Defense for Research and Engineering.

As more people are vaccinated, and the U.S. turns the corner on the disease, a look back at the first year of the pandemic shows the critical role that the MII played in addressing the nation's health and defense needs. The MII's rapid response to the COVID-19 pandemic also shows how it's well-positioned to help mitigate future supply-chain disruptions by applying innovative frameworks that reduce the cost to research, produce and maintain critical technologies and their supply chains.

As part of a whole-of-government effort to build a resilient National Security Innovation Base, the MII is able to quickly and efficiently leverage federal funding and coordinate with the deep and diverse U.S. manufacturing ecosystem to answer federally-sponsored project calls. The MII's flexible business framework enables it to unite funding and manufacturing capabilities with emerging technology ecosystems to accelerate innovative technologies that deliver defense-essential equipment, strengthen local economies, provide educational and workforce development opportunities and solve manufacturing challenges — including those caused by the pandemic. Since the establishment of the first institute in 2012, the federal government has committed almost $1.2 billion in funding to the institutes. A network of over 1,500 organizations from academia, industry and state governments has committed an additional $2 billion in cost share to the MII.

In early 2020, the MII immediately activated its multidisciplinary network of companies and innovators to fill gaps in the PPE supply chain. For example, America Makes, the National Additive MII in Youngstown, Ohio, partnered with several federal agencies to connect the additive manufacturing community with health care providers and communities in need of PPE. Through the National Institutes of Health's 3D Print Exchange (owned and operated by the National Institute of Allergy and Infectious Diseases), America Makes connects manufacturers with free PPE designs that manufacturers can download. As of February, 624 published designs were available on the exchange — 34 designs were optimized for clinical use and 28 were optimized for community use. The designs have been downloaded more than 200,000 times. Through the effort, America Makes assisted frontline workers in obtaining hundreds of thousands of pieces of critical PPE supplies from quality manufacturers across the country.

As a result of America Makes' proactive support in energizing its U.S. community, the DOD subsequently awarded $4.7 million to the institute to enhance and expand its design innovation program, increasing the DOD's ability to rapidly vet, certify and field PPE designs to quickly match supply with demand and recommend improvements. This is one of 13 MII COVID-19 response projects that the DOD sponsored through $60.7 million in funding through the Coronavirus Aid, Relief, and Economic Security Act, and is a prominent example of how the MII provides innovative and accelerated production approaches.

Some of the institutes have also answered the call to use their technologies and networks to respond to the pandemic. Along with the Massachusetts Technology Collaborative, the Advanced Functional Fabrics of America MII has helped administer $5.6 million in funds for PPE through the Massachusetts Manufacturing Innovation Initiative, which is a special partnership between the state of Massachusetts and four of the institutes. AFFOA also leads the development of the first PPE product lifecycle management system, which will allow designers and developers to capture specifications to recreate products and enable the creation of a blueprint for government production of N95 masks to mitigate future shortages. In another effort, AFFOA established a member-based N95 testing network that measured the performance of more than 1,000 types of N95 and KN95 masks and materials.

MII's Manufacturing Times Digital, dubbed MxD, in Chicago, and the Lightweight Innovations for Tomorrow Institute, also known as LIFT, in Detroit, produced and donated PPE to local area hospitals and community centers. Additionally, MxD is executing a supply-chain risk alert project that seeks to leverage machine learning and artificial intelligence capabilities to provide end-to-end visibility into manufacturing supply chains, thereby identifying vulnerabilities, foreign dependencies and potential future disruptions.

BioFabUSA, the MII focused on large-scale manufacturing of engineered tissues and regenerative medicine research, is leading an effort to design and implement a demand forecasting dashboard that will allow medical systems to accurately predict the demand for medical supplies and resources during surges, such as the pandemic. Miami's Jackson Memorial Hospital has already instituted the current version of the demand dashboard to help address critical impacts of surges in COVID-19 cases in the region.

The success of these and other MII COVID-19 responses culminated in a March 24 briefing to Congress. The Manufacturing USA Network — whose members include the nine MII and seven other institutes associated with the Departments of Commerce and Energy — released a 36-page report highlighting the MII's manufacturing leadership during the pandemic.

The MII's effective, agile actions in response to evolving COVID-19

impacts demonstrates its value to U.S. well-being and national

security. Ensuring the long-term health of the defense industrial base

and U.S. technological superiority depends on continued support for the

MII and the transformational procurement pathways it offers so that the

U.S. is ready to face future supply chain disruptions and technology

insertion challenges.