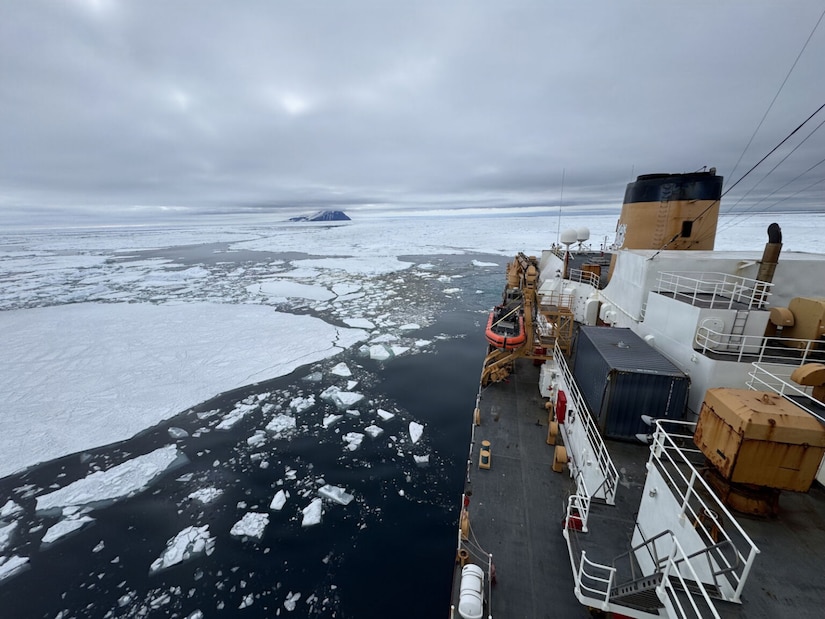

The U.S. Coast Guard cutter Polar Star began icebreaking operations in the Southern Ocean in support of Operation Deep Freeze 26 and marked its 50th year of commissioned service Jan. 17 by freeing and escorting a cruise ship trapped in a pack of ice.

The Australian-owned cruise ship contacted the Polar Star at approximately 11 p.m., local time, Jan. 16, after becoming beset in a pack of ice roughly eight nautical miles from McMurdo Sound, Antarctica. The Polar Star's crew conducted two close passes to break the vessel free, then escorted it approximately four nautical miles to open water.

The Polar Star departed Seattle in November for its 29th deployment to Antarctica in support of Operation Deep Freeze.

The operation provides logistical support for the U.S. Antarctic Program, which is managed by the National Science Foundation. The mission includes strategic and tactical airlift, airdrop, aeromedical evacuation, search and rescue, sealift, seaport access, bulk fuel supply, cargo handling and other transportation requirements.

These efforts enable critical scientific research in one of the most remote regions on Earth. The ship's role in Operation Deep Freeze includes breaking a navigable channel through miles of dense Antarctic ice to allow fuel and cargo deliveries essential for sustaining research stations and operations.

Commissioned Jan. 17, 1976, the Polar Star is the nation's only active heavy icebreaker and has served as a cornerstone of the U.S. presence in the polar regions. For five decades, the cutter has executed missions including Antarctic resupply, search and rescue, environmental protection and national defense.

As the cutter transits the Southern Ocean en route to Antarctica, its crew reflected on a half-century of service defined by resilience, adaptability and dedication.

"I am constantly amazed at this crew's tremendous energy and enthusiasm," said Coast Guard Capt. Jeff Rasnake, CGC Polar Star commanding officer. "Despite the many challenges associated with getting and keeping this ship on mission, they remain eternally positive and committed to meeting the high standards we've set for ourselves."

Throughout its service life, the Polar Star has completed dozens of Operation Deep Freeze missions and numerous Arctic deployments, defending U.S. sovereignty, securing critical shipping lanes, protecting energy and mineral resources, and countering adversarial presence in the polar regions. Despite its age, the cutter continues to demonstrate unmatched heavy icebreaking capability, routinely operating in conditions few vessels can navigate.

"At 50 years old, [the] Polar Star remains the world's most capable non-nuclear icebreaker," said Coast Guard Cmdr. Samuel Blase, the ship's executive officer. "That's a testament to the crews that have maintained it over the decades. With years of service left to give, [the] Polar Star will continue to guide the way in the high latitudes well into the future."

As the cutter undertakes another demanding deployment, its 50th anniversary underscores both the ship's enduring capabilities and the professionalism of its crew.

"While the term 'historic' has lost meaning through overuse, there is no doubt that this is an amazing ship," Rasnake said. "[The] Polar Star's 50 years of service in the polar regions puts it in the discussion with other great Coast Guard icebreakers."

As the Polar Star presses south through freezing seas and thickening ice, the crew carries forward a proud tradition of service. The 50th anniversary serves as both a celebration of the past and a reminder of the cutter's ongoing role at the forefront of U.S. polar operations.